IntuiSwitch™

Turnout Controllers by ESELCO

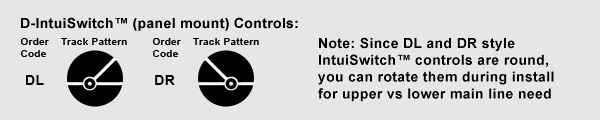

The D-IntuiSwitch™ Control

IntuiSwitch™ turnout controls answer your search for an attractive, easily installed and easy to use method of controlling model railroad turnouts activated by Tortoise™ stall motor switch machines.

Many of you were impressed by our classic IntuiSwitch™ controls, but needed something a little different. Modular clubs needed a flush-mount version that wouldn't easily be damaged with frequent transport of the modules. Others wanted a compact version easily integrated within control panels. Our D-IntuiSwitch™ control addresses both needs. This style has a round body that fits in a one inch diameter hole, and has the graphic graphic overlay already attached. When mounted, the overlay seals flush against the panel. The diameter including the overlay is 1 1/8", allowing the controls to be mounted much closer together than our classic IntuiSwitch™ controls.

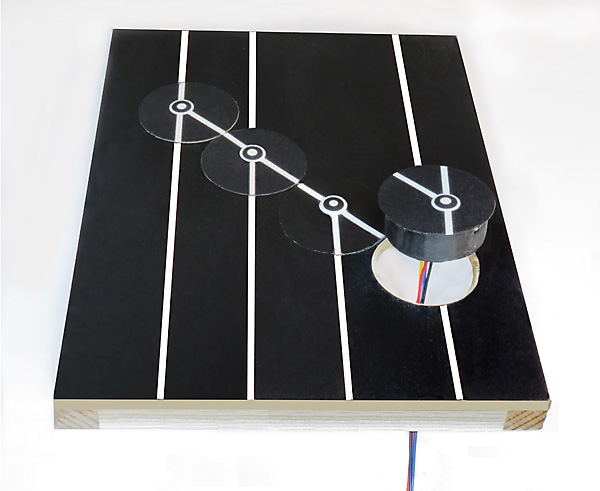

How panels are constructed using the D-IntuiSwitch™

Installation is easy. Decide where to mount it. Drill a 1" diameter hole. Bevel the hole to accommodate the support lip underneath the overlay. Insert the control in the hole. Rotate the control to match the desired track orientation. Remove the protective backing to expose the adhesive, and press the facing against the panel.

Like our classic IntuiSwitch™ control, the turnout status is shown by lights behind the track pattern on the face of the control. The controls are available in right and left hand track patterns, allowing you to match the track patterns of your layout.

Electronics inside the IntuiSwitch translate the press of the illuminated, tactile pushbutton into the proper drive signal for the switch machine. It displays the current turnout position through the backlit housing. When you shut down your layout at the end of the day, the controller remembers the current position of the turnout. When you start your next session, the turnout comes up in the same position, correctly shown on the built-in display.

Installation is quick and easy with a drill and screwdriver - no soldering needed.

Available in different output types. Our standard unit directly drives a Tortoise™ switch motor, while our -H (hybrid) version works with external JMRI or DCC decoder boards which drive the turnouts. To the user, they provide the same consistent interface, allowing a mix of stand-alone and automated turnouts on the same layout. The -H version can be used with non-stall-motor turnout types when paired with an external JMRI or DCC decoder which supports those types.

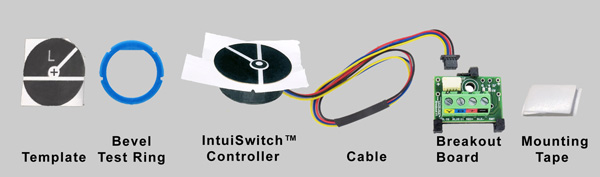

What's included in the package:

Examples of D-IntuiSwitch™ Controls in Use

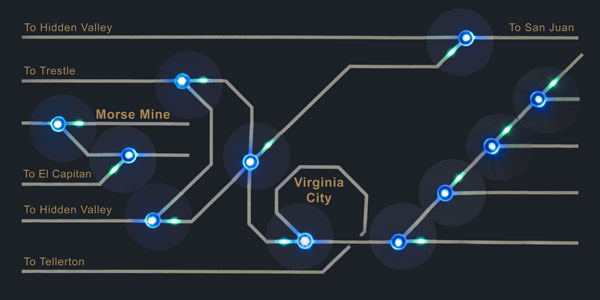

This 10" x 5" control panel for the Virginia City area of Shelly Levy's layout was built using 11 D-IntuiSwitch™ controls:

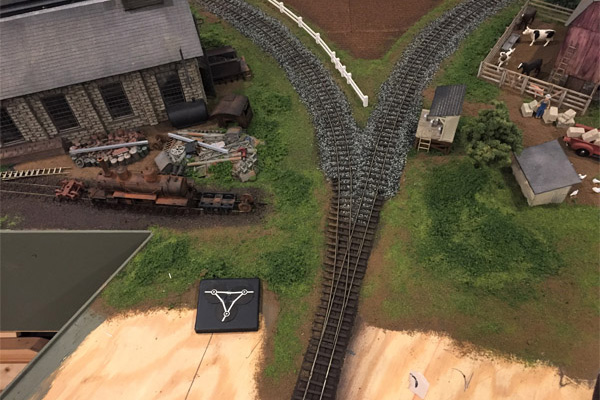

Pete Vollmer's layout includes a wye controlled by three D-IntuiSwitch™ controls.

We are now shipping version 2.0 of the IntuiSwitch™ turnout controls.

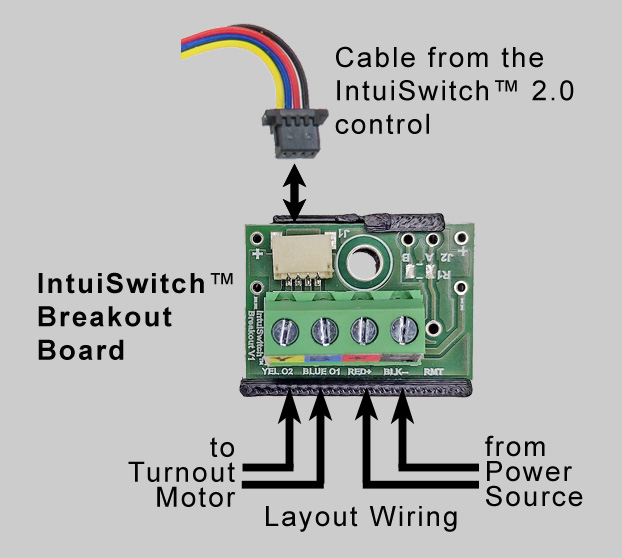

The V2.0 controls include a screw terminal breakout board that simplifies

connecting layout wiring to the controller.

Other features include improved output drive, reduced light leakage,

user customizable pushbutton brightness, and a lockout feature for layouts

used at public train shows.

Installation is simple:

Mounting the D-IntuiSwitch™

- Lay out the panel, using the supplied templates as an aid.

You can download the templates here to get started before purchasing the controls. - Create the track diagram on the panel. You can do this with 1/16" automotive striping tape, paint, or printing the diagram on label material and adhering it to the panel.

- Line the template up with the artwork on your panel.

- Drill a one inch hole in the panel centered on the crosshair of the template.

- Bevel the front edge of the hole to accomodate the small lip beneath the facing at the

top of the control housing that keeps the control from pushing completely through

the hole. You can do the beveling with a file, sandpaper, a hobby knife, or the

optional beveling tool we designed just

for this purpose.

The supplied (non-adhesive) bevel test ring has the same diameter and lip as the control. When you have beveled the hole sufficiently, the top of the test ring will sit flush with the panel when the test ring is placed in the hole. - Remove the bevel test ring, and insert the control in the hole.

- Rotate to align the artwork on the control with the artwork on your panel.

- Remove the backing that protects the adhesive on the outer portion of the back of the facing.

- Press the control the rest of the way firmly into place, adhering it to the panel.

Wiring the D-IntuiSwitch™ Control

The following instructions are for wiring a standard IntuiSwitch control, which directly drives a stall motor switch machine. If you are installing a -H (hybrid) IntuiSwitch control, see the instructions in the IntuiSwitch-H 2.0 Wiring Quick Reference Guide instead.

Choose a location for the wiring breakout board, which provides an interface between the 8" cable

attached to the IntuiSwitch controller and your layout wiring. You can secure the breakout board to

the benchwork using a number 4 wood screw or the supplied mounting tape, before or after attaching

the wires.

Choose a location for the wiring breakout board, which provides an interface between the 8" cable

attached to the IntuiSwitch controller and your layout wiring. You can secure the breakout board to

the benchwork using a number 4 wood screw or the supplied mounting tape, before or after attaching

the wires.- Insert the four-wire cable connector from the IntuiSwitch controller into the white connector on the breakout board, with the cable oriented so the black wire is adjacent to the mounting screw hole of the breakout board. Hold the cable parallel to the breakout board when inserting or removing the cable. The next step depends on the type of IntuiSwitch controller you are installing. If you are installing a standard IntuiSwitch (which directly drives a stall motor switch machine) then:

- Run wires from your power source (12 to 24 volt DC or 10-16 volt AC, or DCC track power to the red and black terminals. (If using DC, wire + to the red terminal, - to the black terminal.)

- Run wires from the yellow and blue terminals to the stall motor switch machine.

The controls are available in the following standard track patterns:

Pricing: D-IntuiSwitch™ V2.0 Controls are $15.95 each.

We accept payment via PayPal and major credit cards.